Blog

The Flamethrower

Intro

Okay so this isn’t actually laser related (though I could add a red dot pointer to it i suppose!) but it involves high voltage, fire, and more… so the boys and I are going to build a flamethrower. We will go over legalities and use cases as well as best practices of design, build, and use with an emphasis on safety and risk management.

I looked at many similar devices, both commercially available and DIY, as well as data on the military equipment. I opted for the fuel pump over having a pressurized tank of ‘gas’ strapped to my back. Those high pressure systems require careful engineering and design to be safe. The system I’m building uses gravity to get the fuel to the pump and it’s only pressurized from the pump outlet to the nozzle. Additionally I will likely have normally closed solenoids both immediately after the fuel tank outlet as well as immediately before the nozzle.

If this fuel pump type device goes well, I may try a pressurized tank system in the future…

Parts List

This will be function over form and likely a crude build initially so bare-bones as far parts go. Here is the parts list so far:

- External Universal Inline Electric Fuel Pump

- 12vDC 60KV High Voltage Generator Module

- Ceramic Electrode Ignition Plug

- Auxiliary Fuel Tank (1L with Vent)

- Mini Momentary Push Button Switch

- 6-6000 Brass Sprayer Cone Nozzle

- 1/8″ Brass Mini Ball Valve

- 1/8″ NPT Brass Nipple 2″ Length

- 1/8 NPT to Male Metric M12 x 1.5mm Adapter

- Rechargeable 12V 3250mAh Battery Pack

- 1/8″ Solenoid Valve Normally Closed (2)

- Various Wire Ties

- Various Adhesives

- Various fuse holders, connectors, ferrules, etc…

- 16AWG stranded 100% copper power wire

- Various Tools

- Various Fire Suppression Equipment

- Various PPE for High-Voltage, flash burns, eye protection, etc…

- and more

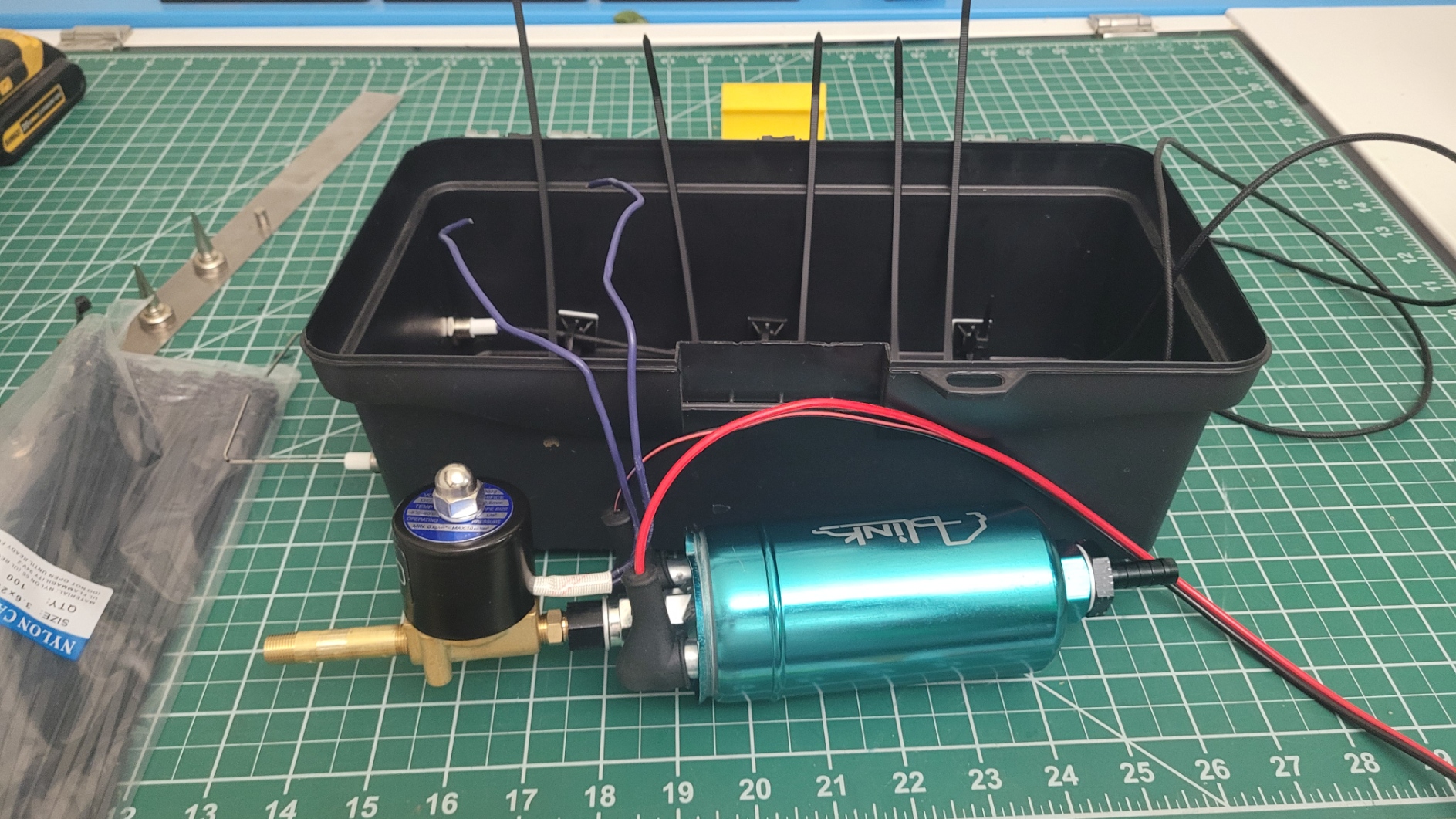

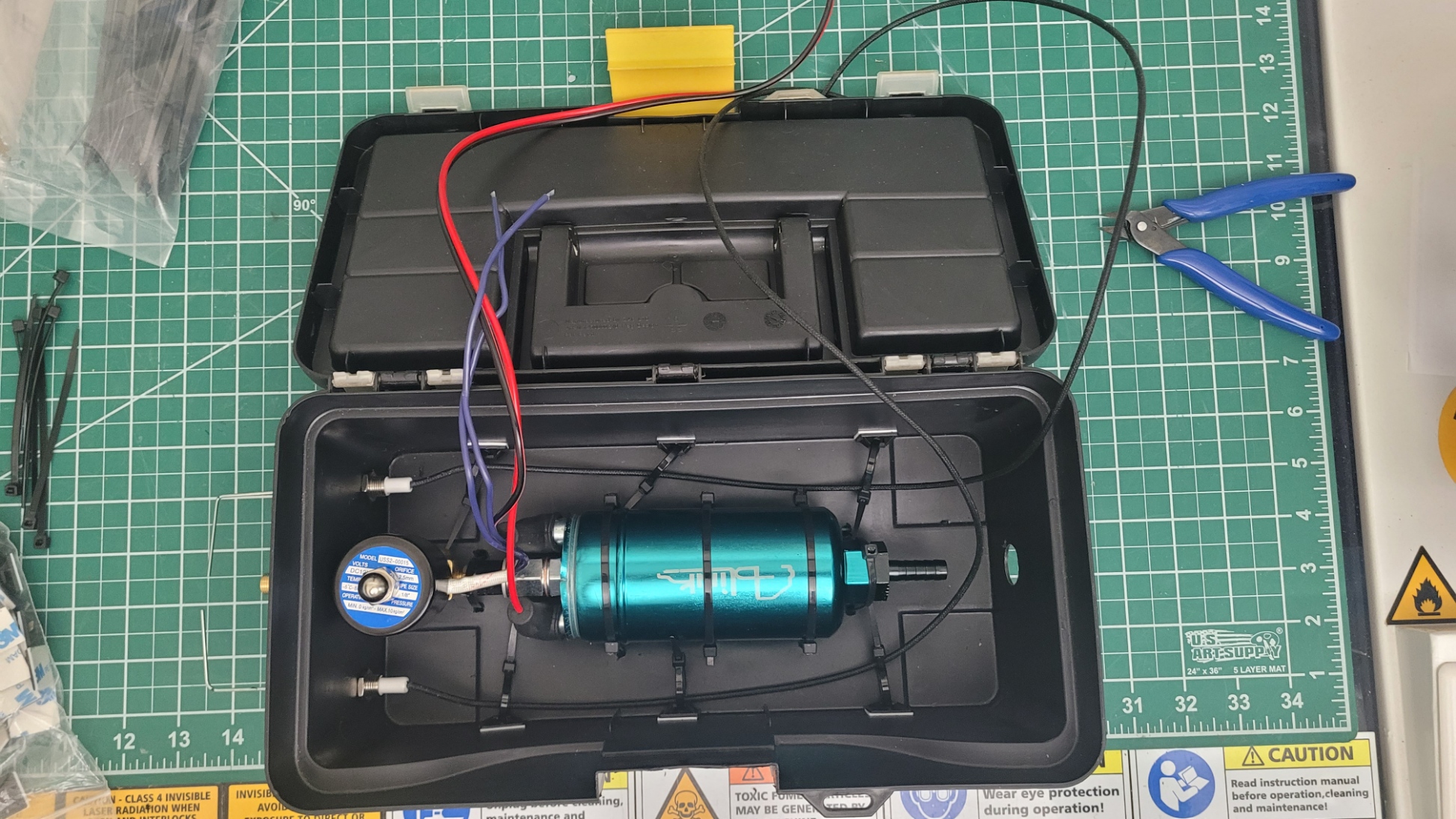

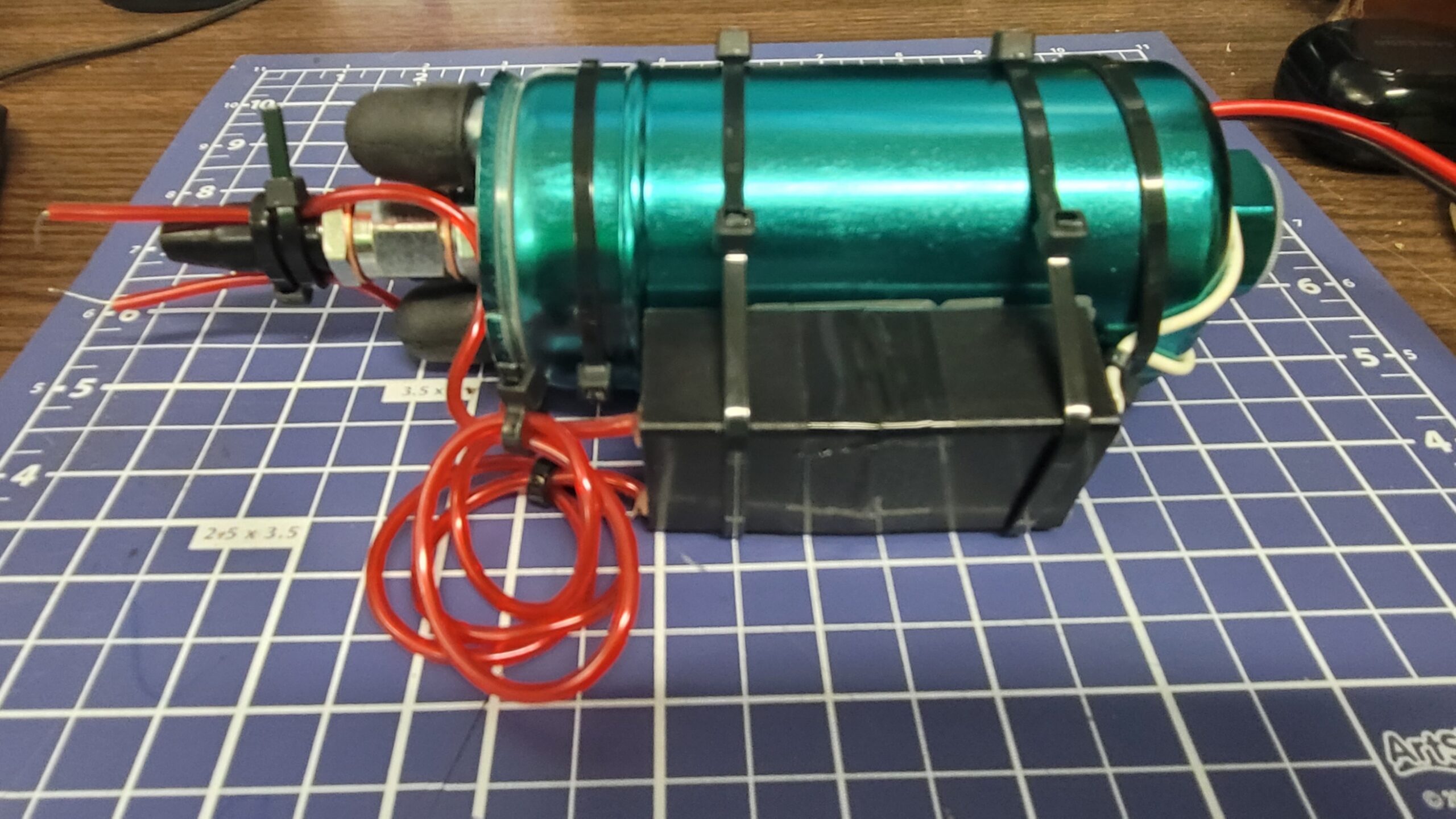

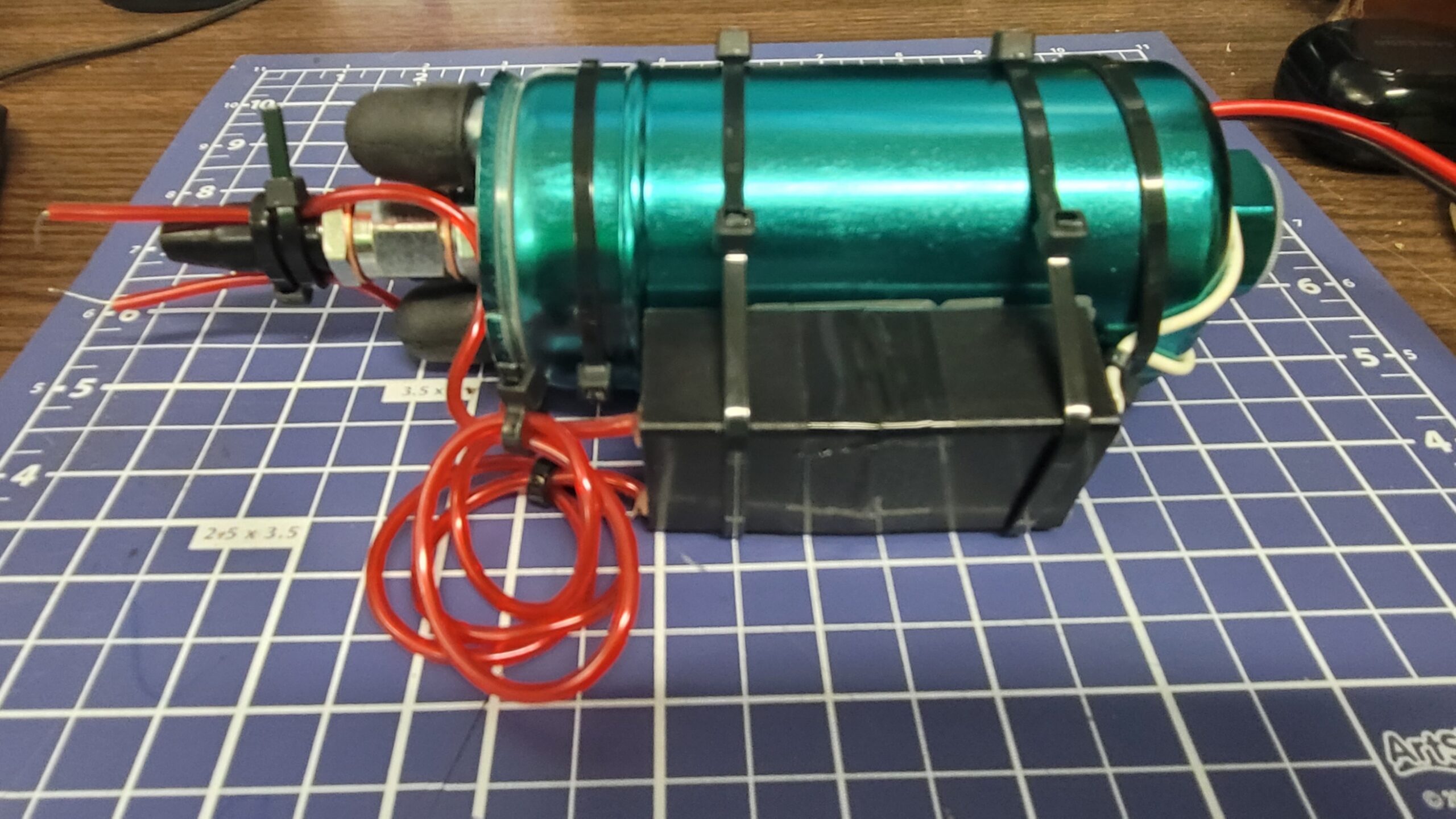

Proof of Concept

Here is a short video of the main components temporarily fabbed up and having power applied for 10 seconds or less to test and get proof of concept:

And here are some videos on some of the initial systems checks:

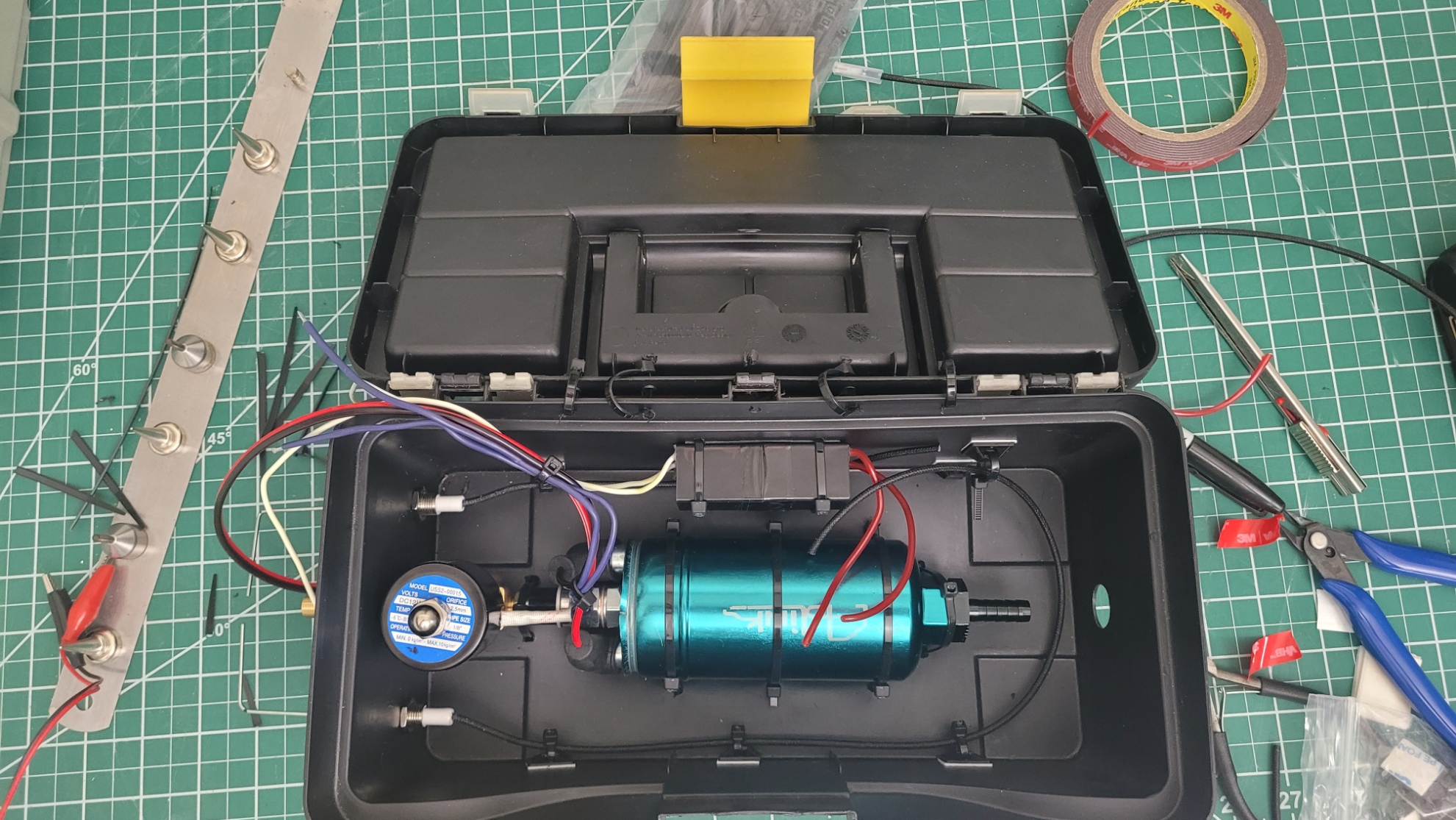

The text fixture build is almost complete. Here is an update:

First Live Fire Test

The first test fire of the unit was lackluster at best. I think the safety solenoid is the issue along with DC input power. The pump will deliver ~300LPH at ~40psi and the solenoid, when open, will only flow ~52LPH. So it appears that the solenoid is severely restricting the flow. I will eliminate it and retest. I also will upgrade the DC power Supply from a 12v 3300maH pack to dual 7maH SLA Batteries.

Okay... Its time for Phase 2

This is what Phase 2 looks like. i removed the solenoid and added a manual ball valve just before the nozzle to eliminate flow restrictions. And I got rid of the 2 relays and low current switches. Instead I’m using switches rated for the voltage and current draw of the system. So most of this was simplifying the design, and i put it in a better test fixture than an old plastic toolbox LOL.

MORE TO FOLLOW – CHECK BACK OFTEN – GET OUR NEWSLETTER FOR UPDATES HERE.